ASSET MANAGEMENT SOFTWARE

Our Asset management solution is designed to help organizations monitor and manage their assets using a systemized approach. Managed effectively, the benefits include improvements to productivity and efficiency which places a business in a better position to increase their return on investment.

We provide passive UHF and HF RFID tags for harsh environments. These durable tags are utilized on assets in industries such as Power, Manufacturing, Factories, Marine, Oil & Gas, Transport, Mining, Lifting and other industry that require unique, ruggedized inventory and asset tracking solutions.

Our solutions come complete with RFID readers and mobile handhelds for UHF and HF tags, as well as adapters for mobile devices.

HELPS YOU TRACK THE UNTRACKABLE

Ultra-durable RFID tags and RFID readers help make Asset Management simple for your most challenging classes of equipment, such as lifting equipment, hose, pipe, tools, pumps and valves etc. Contact us to learn how to help your team improve safety, reduce paper and drive operational efficiency.

- Our software streamlines all equipment safety processes, conserving both time and effort.

- Our software allows you to cut costs while not compromising your safety.

- Our equipment safety certificate system keeps cost effective safety at your fingertips.

- Our pricing model helps you keep using the system while only paying for what you need.

Oildfield / Downhole / Hydraulic Fracturing

Based in the oilfield sector, Our products has worked with drilling, fracking and offshore clients around the world. Featured Equipment: Downhole tools Flow line components (iron) Pipe Pumps & Valves Hose Rigging

Key Features:

- Embeddable ultra durable RFID for downhole, subsea or surface deployment

- Banded and epoxied RFID tags for high demand in this sector

- Mobile application for onsite identification, inspections, inventory and replenishment

- Online database with test certificates and inspection history

- Integration to hydrostatic and MPI testing applications including API 6A/16A

- Auto email overdue schedules

- Free end user smart phone application for on site identification and safety history

Problem: Industrial Hose Compliance

- Hoses must adhere to regulated or internal hose policy

- Inspect, re certify and replace hoses

- Keep track of when hoses are due and re order replacements

- Accurately record information on each hose

- Keep records over entire lifetime of hose, even after it is scrapped

Solution: Software Implimentation

- Automatic inspection and replacement reminders

- Email automatically sent

- Detailed inspection forms with diagrams

- Replacement forms to keep records of when hose replacements occurred

- Our Solution can tie into any ERP system to automatically send order for new hose upon replacement

Problem: Problem: Motor Failure

- Each failure can cost thousands of dollars

- Most motor failures are the result of forgotten maintenance

- Causes: bearing failure, electrical overload, low resistance, over heating, contamination, and vibration

- Proper and timely lubrication can reduce costs by 70% 4

- Electric motors account for 78% of energy costs in industrial systems 5

- Reduced production efficiency due to decreased motor efficiency

Solution: RFID-based Maintenance Scheduling

- Automatic maintenance reminders

- Lubrication replacement

- Clearing of dust and contaminants

- Belt replacement

- Maintenance/Inspection forms with step by step walkthrough of task

- Lower energy costs, repair costs, and downtime

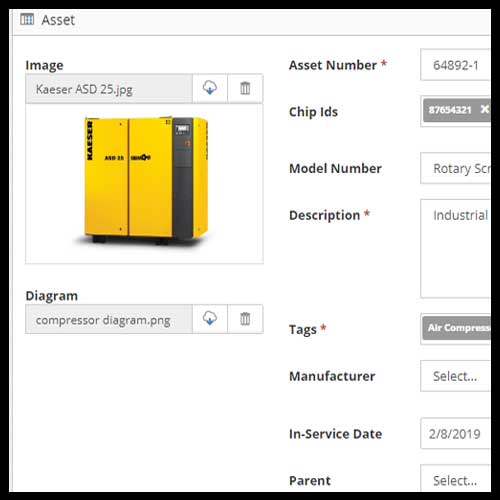

Problem: Problem: Air Compressor Failure

- #1 cause of compressor failure is lack of proper maintenance

- Compressor failure most often causes an entire plant shutdown

- Leaks in the airline are the largest factor for electrical costs relating to air compressors

- Compressor records are usually kept in a separate area from other equipment, leading to lost documents

Solution: RFID-based Maintenance Scheduling

- Automatic maintenance reminders to yourself as well as the compressor technician

- Don’t require all of the maintenance information on the form, just enough to keep record it was completed

- Optional : Tie into SAP system and pull information from invoice for maintenance to push into TESSALink

Problem: Problem: Hydraulic Pump Failure

- Thousands of dollars per pump failure

- Tens of thousands including maintenance resources, lost oil and production 6

- Fluid contamination, vibration, pressure, temperature, bent vanes, improper lubrication

- Hard to maintain and check with in house personnel

Solution: RFID-based Maintenance Scheduling

- Similar to motor maintenance

- Automatic maintenance reminders

- Lubrication replacement

- Clearing of dust and contaminants

- Test discharge pressure and fluid for contaminants

- Maintenance/Inspection forms with step by step walkthrough of task

- Can include diagrams and images for more complex areas

- Reduce failures and repair costs

Problem: Problem: Safety Equipment not Meeting OSHA Standards

- OSHA fines for safety equipment being expired, damaged, improperly used, or any other violations

- Fall protection, scaffolding, respiratory protection, ladders, industrial trucks, electrical protection, etc.

- Inspections required on safety equipment

- OSHA standards for equipment may differ from in house requirements

- Increased risk for workers using equipment not properly inspected

Solution: RFID-based based Inspection Scheduling

- An RFID based maintenance/inspection program helps keep track of any safety equipment that requires inspections

- Check in/check out forms help keep records of employees using equipment as well as # of uses

- Lockout/tagout tracking

- Protect against liability with clean, up to date records

- Monthly/Weekly/Daily emailed reports of equipment requiring inspection